- Technology

- Scan/toolpath generation

Scan/toolpath generation

Intelligence brought into the LMD process

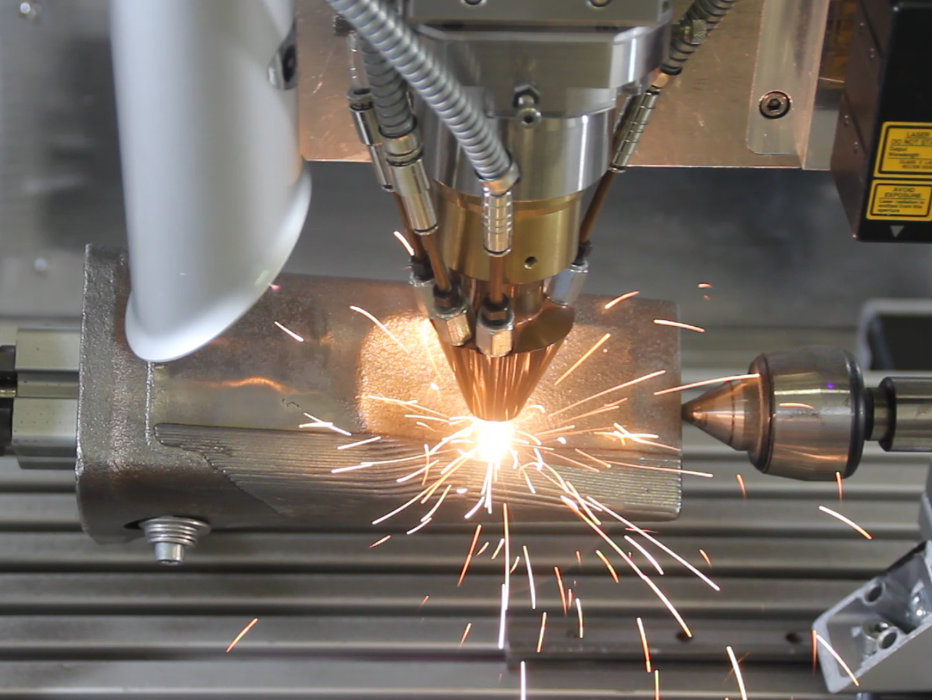

LMD has been used very successfully in various applications for many years. With the conventional LMD process, however, econmic feasibility is often doubtful. In the case of coating or repair applications, the most important aspect is the time that is required to carry out the complex toolpath programming. This is similar with the additive manufacturing of 3D components. In this case however, there are even more fundamental obstacles to be overcome, as the quick and reliable generation of a suitable CNC program from CAD data often appears to be almost impossible. Not to mention tasks that were previously considered unsolvable, such as the automated build of 3D geometries on existing, non-CAD-documented parts.

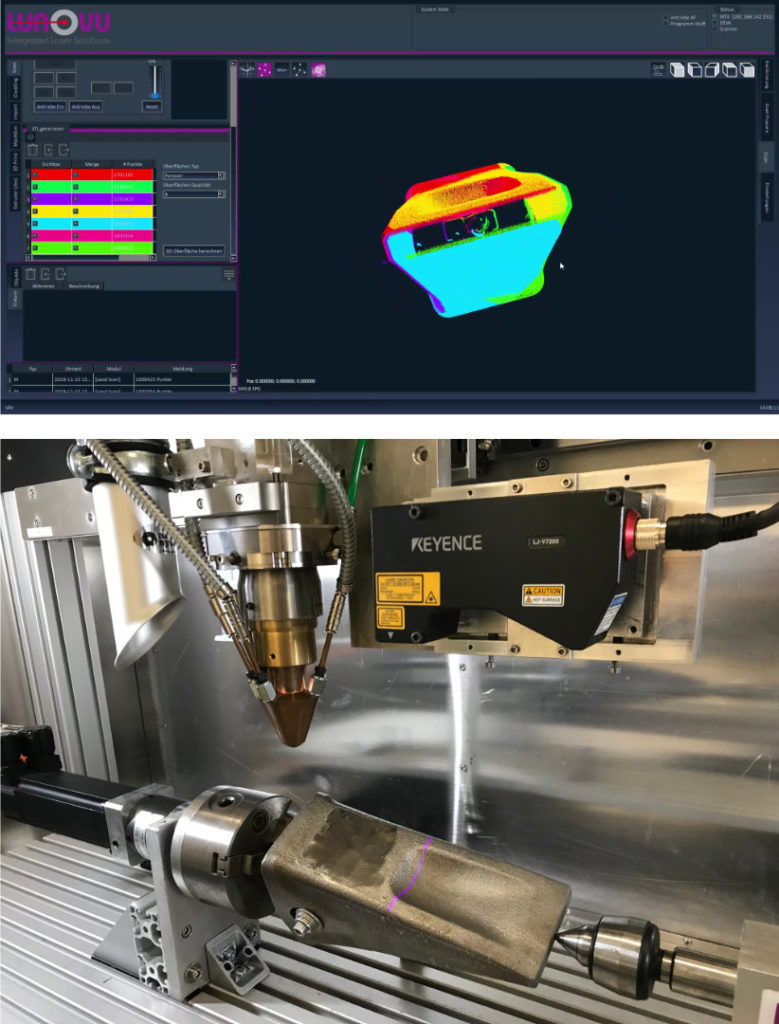

LUNOVU has developed a holistic solution for all of these questions. The combination of surface recognition sensors with the specially developed software components of the LunoSUITE brings intelligence into the LUNOVU LMD systems. This frees you from time-consuming and error-prone programming tasks, and in many cases even enables previously unthinkable applications to be covered. LunoSUITE consists of the components LunoSCAN, LunoCOAT, LunoBUILD and LunoSIM, which provide the complete digital process chain from 3D component acquisition to toolpath planning for coating, repair and additive manufacturing applications, and finally simulation.

All software components are subject to a common architecture, have a uniform appearance and are used via a single, intuitive user interface. The core of the technology developed by LUNOVU is a toolpath generation module. For arbitrary 3D geometries, it precisely calculates the movements of the LMD processing head that are required to build up the volume path by path. Extensive LMD process knowledge and a large number of parameters are employed. The path generation module is generic and can be used for various CNC machine configurations as well as for robots using add-ons created by LUNOVU. At the same time, various applications can be addressed, some of which have their own software modules.

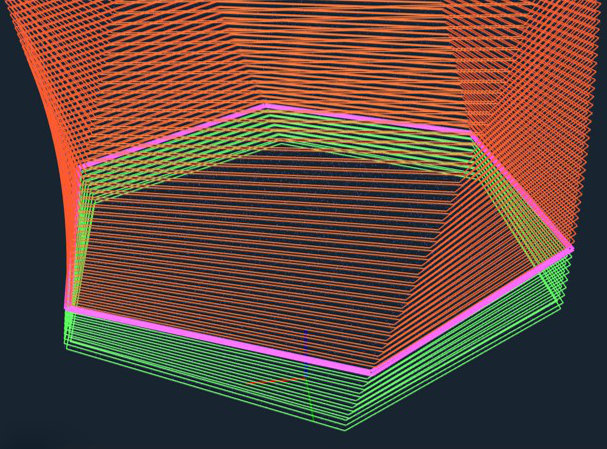

LunoBUILD

is a software module for the layer-by-layer build of 3D components on flat substrates. Similar to the well-known plastic 3D printers, LunoBUILD breaks down a 3D model into thin, stacked layers (“slicing”), for which the LMD paths for building up these layers are automatically calculated. At the same time, the software uses the correct parameters for all process-relevant variables, such as laser power, powder parameters or feed. The result is a completely automatically generated program for building up such a component layer by layer, which can be executed immediately. By default, the programs generated with LunoBUILD control a 3-axis configuration; for up to 5 axes there are more complex but also proven solutions available. Very often, however, LMD users have to solve tasks that deal with the build of layers, layer packages or 3D structures on existing components. Often such freeform surfaces are not or only insufficiently documented by CAD data. While conventional LMD systems require very extensive programming work at this point in order to create the required machine programs, LUNOVU offers a unique and extremely economical method to carry out reliable LMD processes in the shortest possible time without manual programming, simply using the LunoSCAN and Luno BUILD modules.

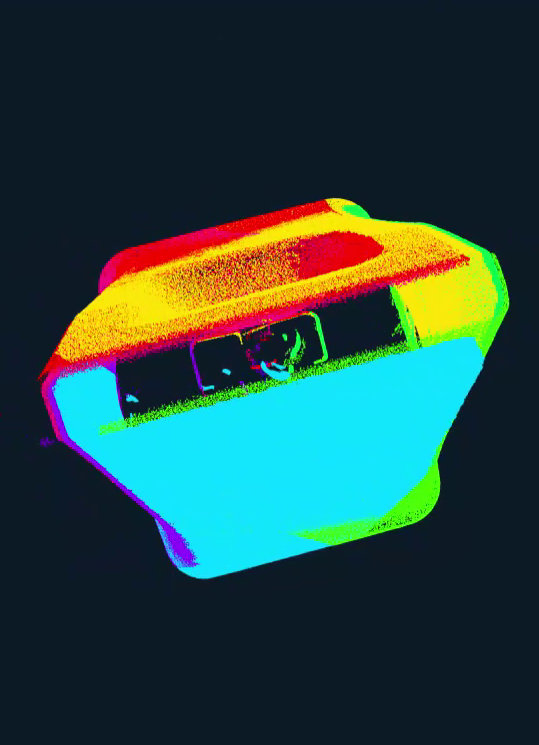

LunoSCAN

uses profile data from a 2D laser line scanner, which is permanently connected to the processing head and can therefore be moved by the axes system. The scanner records the component surfaces with high resolution and delivers raw 3D data. These are processed in complex algorithms in the LunoSCAN software. Multiple passes as well as scanning runs at different tilt angles can be implemented without any problems so that undercuts can also be detected. Finally, 3D models in STL format are generated from this. These models can be visualized on the PC and represent the basis for subsequent toolpath generation steps.

LunoCOAT

allows the user to define the contour of a coating area on the 3D model of the scanned component with just a few clicks of the PC mouse. After entering the desired build height or number of layers, the system can either use stored process parameters (track widths and heights, build strategies, etc.), or the user defines them himself in an intuitive dialogue. In both cases, the toolpath generation module immediately calculates the paths and the executable machine code. In most cases, the entire process from the scan to the first deposited LMD tracks only takes a few minutes!

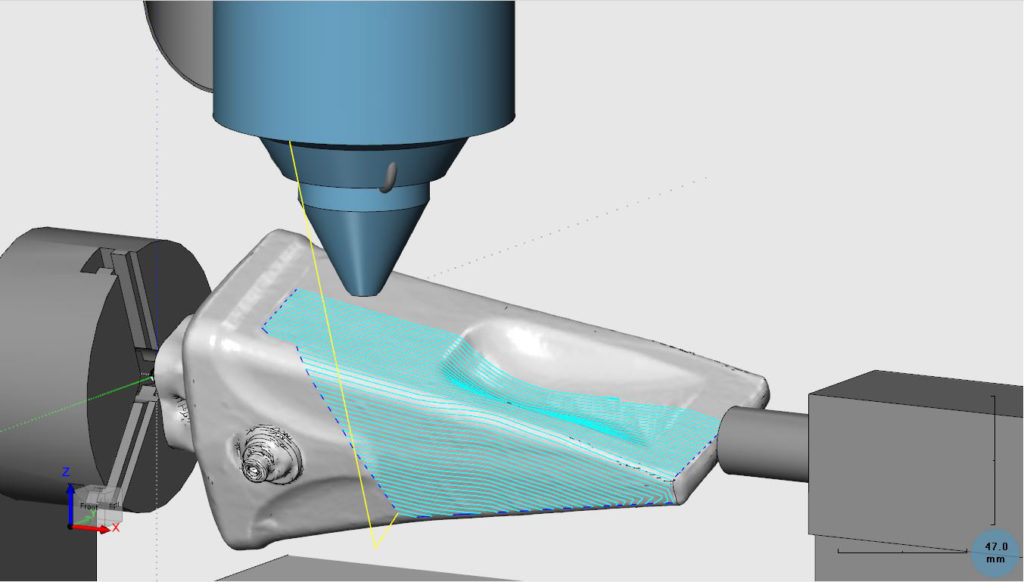

LunoSIM

is another important component of the LunuSUITE package. It often makes sense to first perform a simulation of the machine movements. Particularly in the case of complex processing tasks, it is easy to check whether there is a risk of collisions or whether, with a view to the optimal process result, a changed path strategy might be useful. The LunoSIM simulation shows the actual system including all interfering contours and uses precisely stored characteristics of the kinematics. The execution of the machining program created is then just another click of the mouse.