Economical wear protection

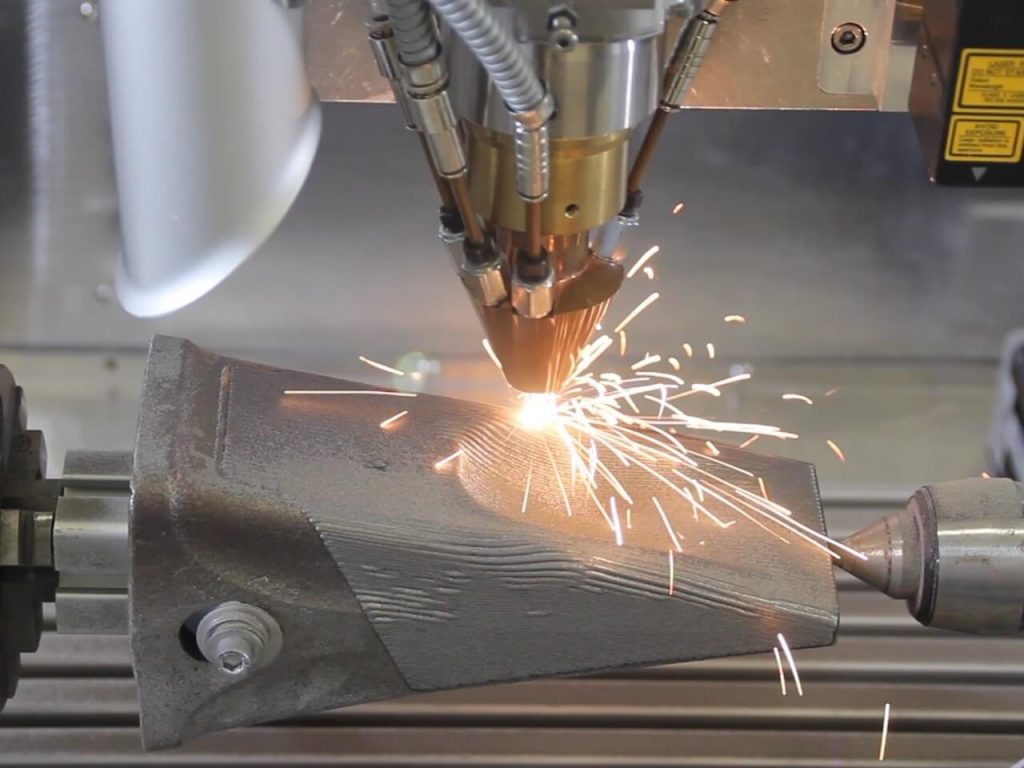

The advantages of wear protection coatings product with laser cladding/DED have been known for a long time and are used in a wide range of applications. Such coatings are performed in LUNOVU LMD machines on small to very large components, both in robot-based and gantry systems.

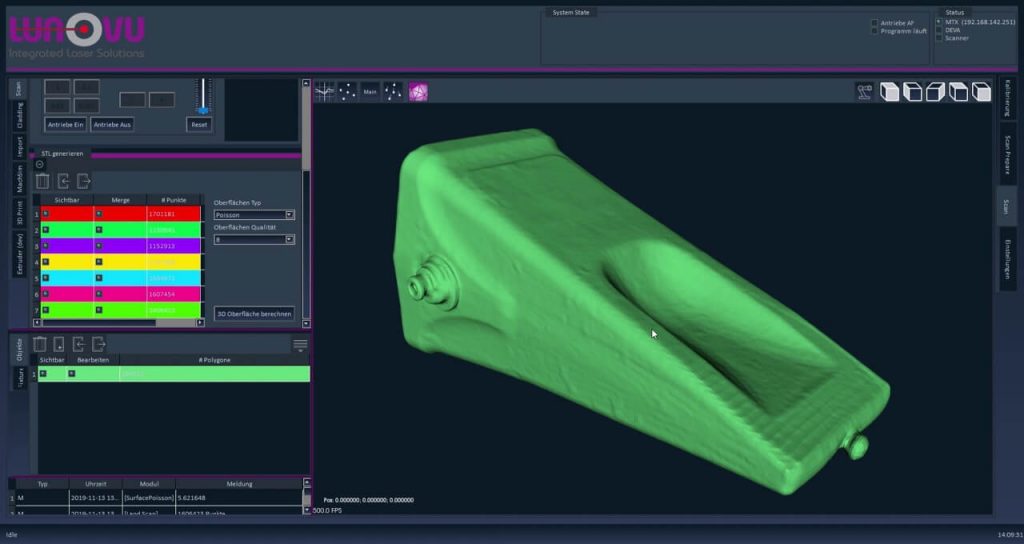

Scan based 3D laser cladding without CAD data

In conventional DED / laser cladding systems, three-dimensional free-form surfaces that are insufficiently documented by CAD data require time-consuming manual programming. This makes laser cladding of complex 3D surfaces often uneconomic. In contrast to that, LUNOVU DED systems scan component surfaces to be coated directly in the machine, allowing the operator to define the coating areas with just a few mouse clicks. Everything else is taken care of by the intelligent DED system: the calculation of the 3D tool paths that precisely follow the contour of the component, the visualization on the PC, and finally the generation of the CNC or robot program.

Senor assisted laser cladding

In many cases, the complete 3D recognition of a component is not necessary. Nevertheless, it is often useful to have the position of the cladding tracks automatically adjusted to the geometry of a part. This is important for large components where thermal expansion changes the actual geometry, or for parts that have not been manufactured exactly to CAD specifications. The LunoCLAD solution precisely applies coatings along geometric features such as edges using an optical sensor system for each specific part.

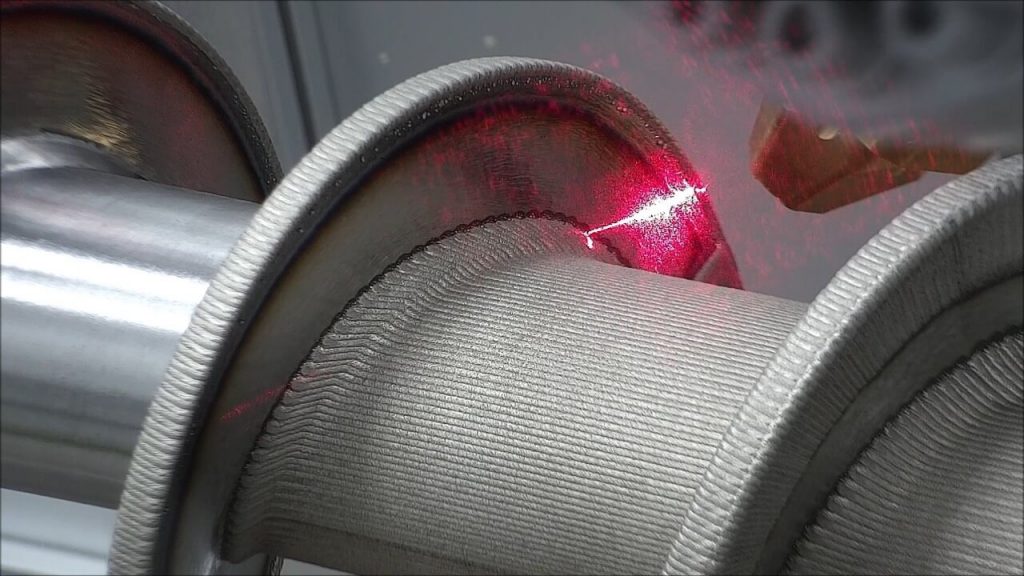

EHLA/High Speed Laser Cladding

Thin wear protection coatings on rotationally symmetrical components represent another important application. The EHLA process (extreme high speed laser cladding) developed at the Fraunhofer Institute for Laser Technology is used for this purpose. This process allows applying layers that are only a few 100 µm thick in a very homogeneous and smooth manner. Therefore, it represents a resource-saving alternative to conventional coatings such as hard chrome plating.

LUNOVU has developed a number of solutions for the EHLA process which, by means of process monitoring/sensor technology, help to significantly increase reliability and economic efficiency.