- Machine Solutions

- eLMD - compact systems

eLMD compact systems

Your entry into the world of Additive Manfacturing

eLMD by LUNOVU is a series of machine systems, with highest flexibility and compact dimensions. At the same time, it offers the full functionality and performance of larger LMD systems. This is why eLMD is the preferred choice in research and development, for pilot and small series production as well as for special applications. Like all LUNOVU LMD systems, it can be equipped with all components of the unique scan/toolpath generation sytem LunoSUITE – LunoSCAN, LunoCOAT, LunoBUILD and LunoSIM.

Unlimited possibilities

Flexibility is a key issue for many of our customers. As additive manufacturing is a relatively young technology, almost every day new application areas and processes show up. This is why a compact LMD system should be based on proven technology on one hand. On the other hand, it must offer a maximum expandability and flexibility! Our developers have managed to bring these two worlds together. A robust design which has been improved through the years, proven components like laser, optics and powder supply and a state of the art control unit guarantee maximum reliability. A large variety of options, like additional axes, components for wire based processes, sensors, automated toolpath generation and much more is available to find a tailored solution for every user. Beyond that, the LUNOVU engineering team implements customer specific add-ons in various areas, such as special software solutions, mechanical extras or hybrid processes.

How open can a system be?

Very open, we believe. During the development of eLMD, the idea of an entirely open system architecture was paramount, especially for the control system. It is part of the LUNOVU DNA not only to use modular and extendible control hadware, but also to develop a control software that offers a maximum of open interfaces to the outer world. If desired, we provide customer specific interfaces or special functionalities. This opens eLMD users a straight-forward path towards the implementation of their specific applications.

eLMD details

The basic system is available in a 3 axes or 5 axes configuration. It includes an XY axes system that moves the processing head, and a Y table that moves the work piece (in 3 axes operation) or the turn/tilt table (in 5 axes operation). Standard travel ranges are 300 mm to 500 mm. The turn/tilt unit has a tilt angle of 0…90° and a turn table with endless rotation for the work piece holder.

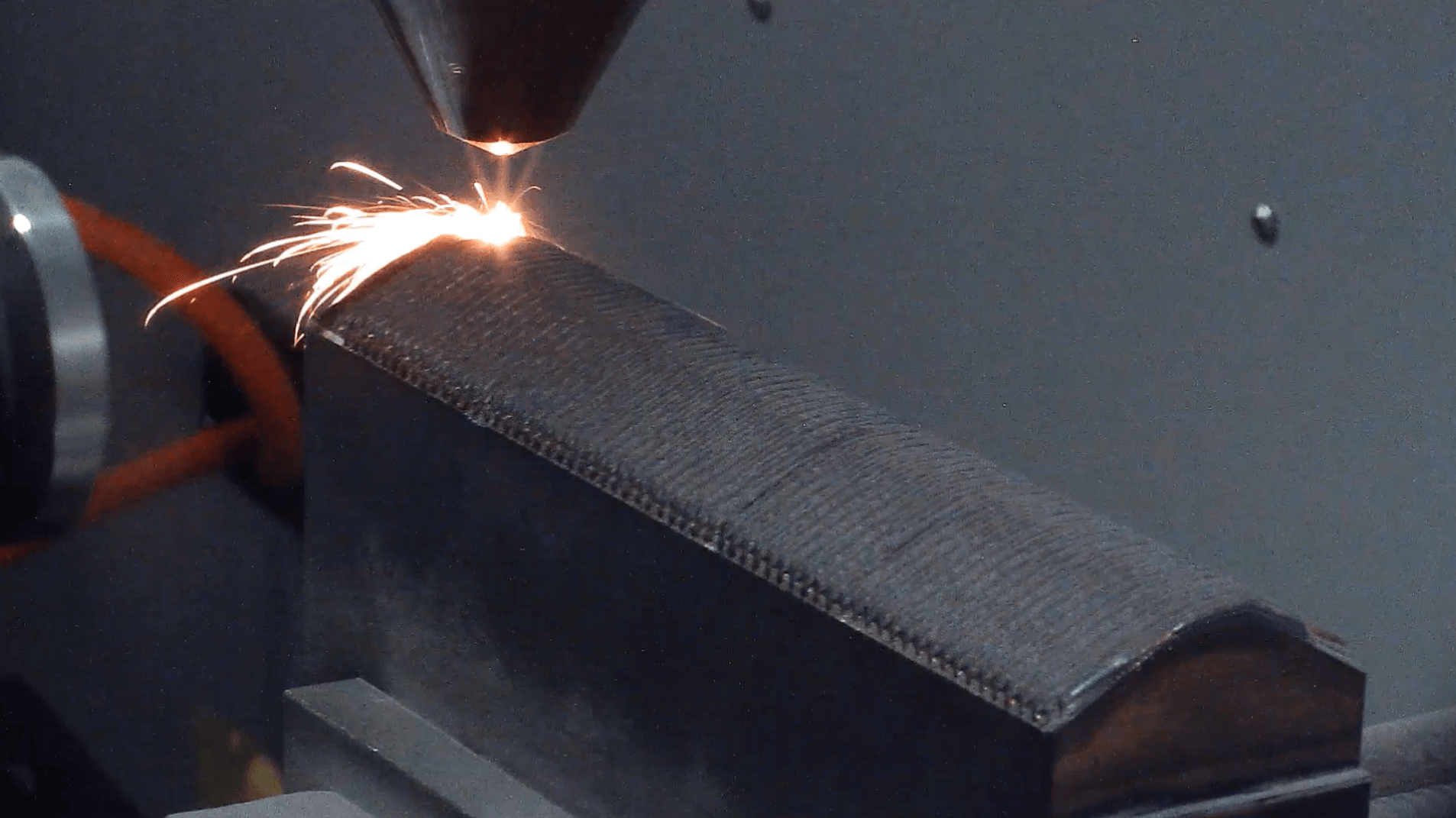

Beam sources are direct diode lasers with output powers between 2 and 4 kW. Alternatively, fiber or disk lasers are also available. Depending on the selected beam quality, fiber diameter and optic, spot sizes between 0.5 mm and 2 mm or larger are used. A large variety of annular gap or multi jet powder nozzles is available, as well as powder feeders with one or multiple powder containers.

Alternatively, the systems can be equipped for wire-based processes. In particular, multi-directional wire deposition heads are available, which can also be used seamlessly with the LUNOVU scan/toolpath generation technology.

The eLMD systems comes with a laser safety housing (laser protection class 1). It is easily accessible through a safety door with window. Another safety feature is the extraction and filter unit. The CNC control unit is based on Siemens SINUMERIK One with LUNOVU specific add-ons, extra functions and user interfaces.

A variety of materials and processes is already pre-qualified. Corresponding processes can be provided with the machine. Material classes include steel, nickel or cobalt base alloys, aluminum alloys or special hard facing mixtures such as carbides in nickel base matrix.

eLMD systems are prepared for upgrades. These include the LUNOVU scan/toolpath generation module, the LunoCAM module, thermal cameras, extra axes, clamping tools etc. And of course anything else that might be required turn your ideas in additiive manufacturing into reality.