Sustainability through Laser Cladding

Machines, equipment and components in agricultural and environmental technology are subject to very special requirements. They are often in constant contact with sand, earth, rock or other highly abrasive materials. Therefore, an anti-wear coating with suitable materials is crucial to minimize wear. This not only results in economic benefits such as longer service life, lower maintenance requirements and reduced costs. There is also a decisive advantage from an ecological point of view, as components can be used for longer and need to be produced anew less frequently.

Multiple applications – one solution

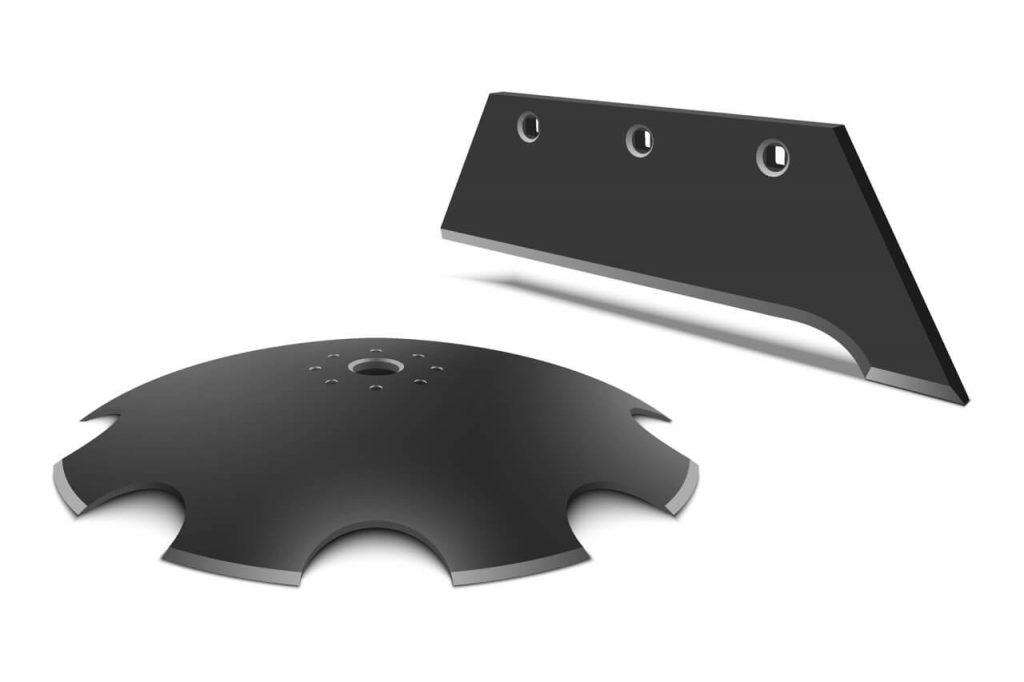

LUNOVU laser cladding solutions exist for many different applications. These include, among others:

- Screw conveyors for biomass

- Screw conveyors for waste water

- Screw conveyors for animal feed

- Blades for feed mixers, choppers

- Cultivator shares

A variety of wear protection materials can be used for this purpose, such as cobalt or iron-based alloys or tungsten carbide/nickel-based materials.

Automation cuts cost

Despite the diversity of applications in the agricultural and environmental sectors, they have one thing in common: maximum efficiency is required in all cases. Therefore, LUNOVU offers proven automation solutions to achieve the best possible productivity. To achieve this, individual solutions are designed for each customer.

We will be happy to show you various automation options. These include:

- Rotary indexing tables, which allow loading/clamping in parallel with machining.

- Robot loading, which allows the machine to be operated automatically for longer periods of time.