- Machine Solutions

- iLMD inert gas systems

iLMD inert gas systems

Additive Manufacturing in inert gas environment

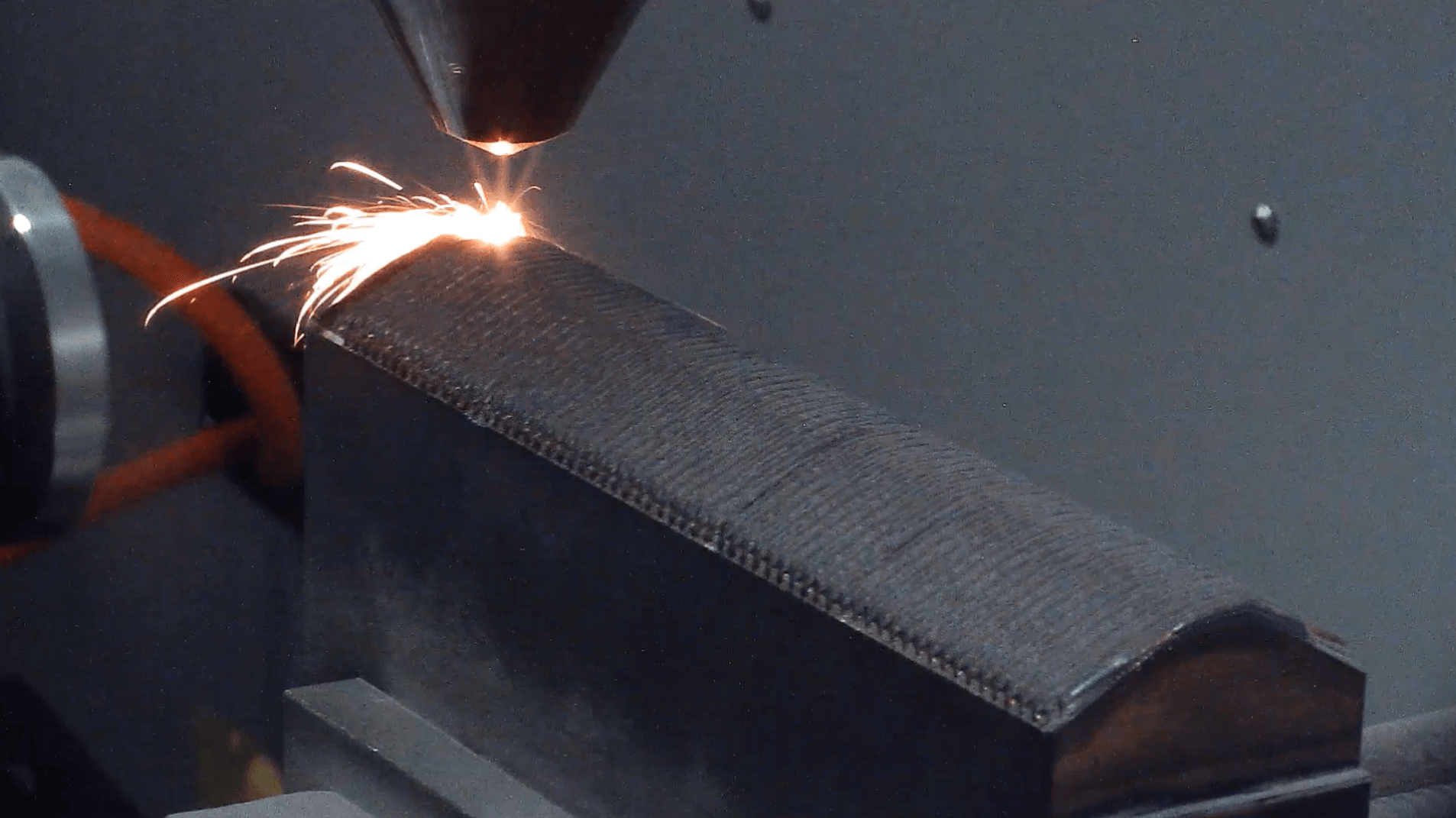

LUNOVU LMD systems can use and manufacture a variety of materials. In most cases, the shielding gas that is fed in via the powder nozzle is sufficient to keep the ambient air away from the melt pool. For certain materials, however, a completely air-free environment is necessary. For these cases, LUNOVU has developed the iLMD systems, in which the entire work area is permanently flooded with protective gas – in most cases argon. This way, extremely oxygen-sensitive materials such as titanium alloys are manufactured in the highest quality.

Complex technology in a user friendly design

LUNOVU iLMD systems are designed for maximum process reliability in an inert gas environment. Of course this means some additional technological effort. Nevertheless, the LUNOVU developers have stayed with their philosophy of creating user-friendly systems. This does not only mean a clear design and easy-to-use components and user interfaces, but also the consideration of ergonomic aspects. As with all LUNOVU machine systems, the experiences of the users from daily practice have been incorporated into the design in order to create the perfect machine solution.

iLMD details

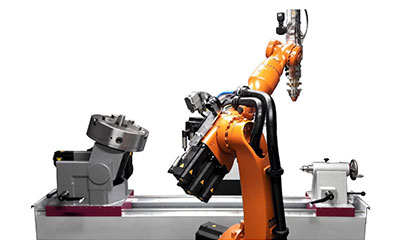

LUNOVU iLMD systems have cartesian XYZ kinematics that move the machining head or the workpiece. The entire kinematic system, the workpiece holder and the processing head are surrounded by a gas-tight housing that is permanently flooded with protective gas under a slight excess pressure. The protective gas circulates through the system in a closed circuit and is constantly cleaned of oxygen and residual water in a filter unit so that residual impurities only occur in the low ppm range. The filter unit can be regenerated, providing a perfect protective gas atmosphere in the long term with low operating costs.

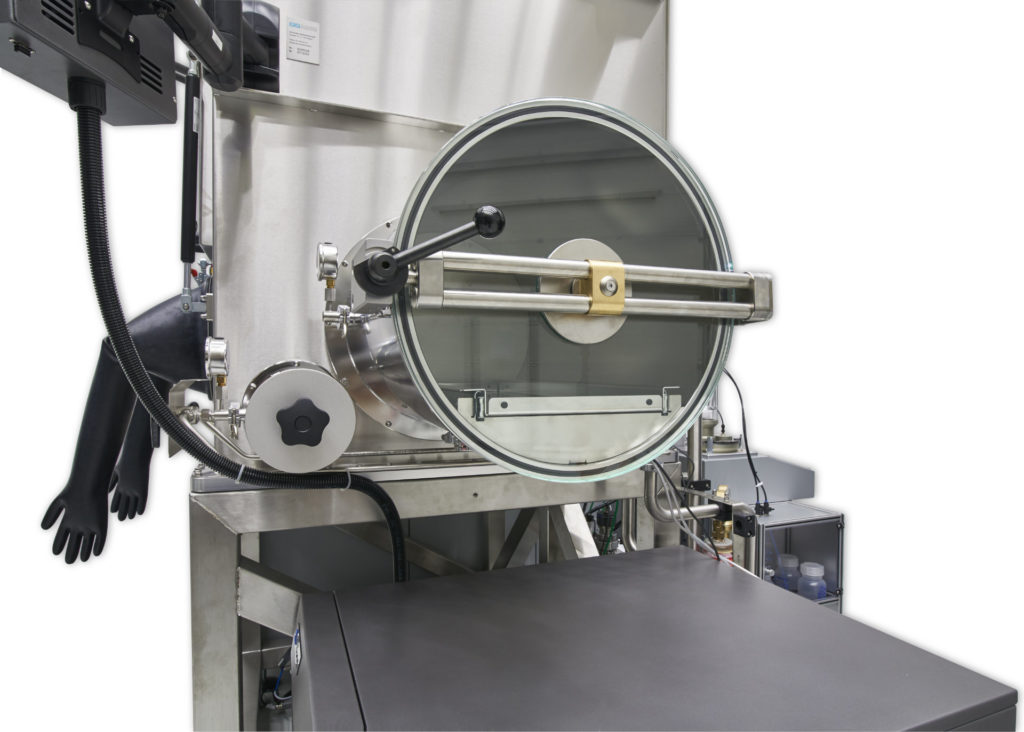

The protective gas cabinet also serves as a laser-safe housing (protection class 1 outside). For loading and other manual activities, gas-tight gloves are used. During the manual activities, the view of the work area is given through a large size window. For laser operation, the viewing window is closed in a laser-proof manner, whereby the view of the processing location is maintained through an additional laser protection window. The glove entrances and any other entrances are also sealed in a laser-proof manner. Laser safety is permanently guaranteed by the safety system with integrated safety contacts at all entrances.

Samples, workpieces and tools are transferred in and out of the system via two vacuum load locks of different volumes. This allows materials to be brought in and out of the glovebox quickly without reducing the protective gas quality.

The size of the machining area can be customized. Likewise, diodes, fiber or disk lasers with appropriate fiber optic cables and optics can be used. A variety of powder nozzles (annular gap or multiple jet, round or rectangular spot) is available, as well as powder feeders with one or more powder containers.

iLMD systems are prepared for expansions, like additional turn/tilt axes for 4/5-axis operation, LUNOVU scan / toolpath generation technology, LunoCAM, pyrometers, etc.