- Machine Solutions

- pLMD production systems

pLMD production systems

Productivity for industrial applications

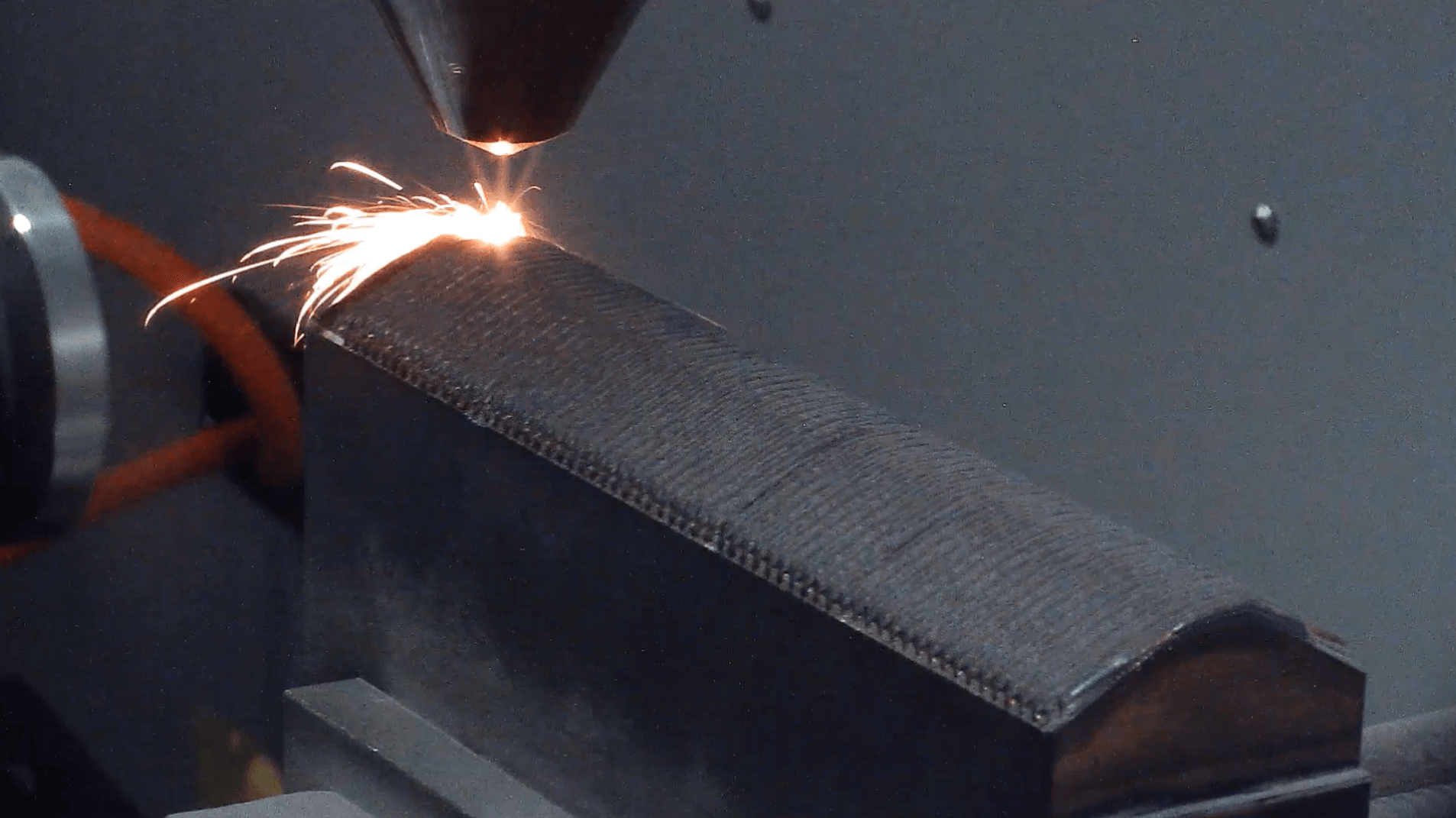

LUNOVU pLMD machines are production systems with medium to large size working volumes. Maximum productivity is first priority. Used for coating applications, tool and mold making or for repair applications, users appreciate the robust design and its economical operation due to the unique scan/toolpath generation technology.

Designed by users for users

No one knows the requirements to a production LMD system better than its user. This is why the LUNOVU developers have taken the time to get a clear picture of these requirements, in many discussions at trade fairs, conferences, in our application center or, even more important, when visiting customers. The result is an extremely robust machine system, capable of handling large and heavy parts. At the same time it makes use of the proprietary LUNOVU scan/toolpath generation technology. Many LMD applications can be covered with minimum programming effort. Even beginners without process know-how can manage complex LMD tasks after having received a short training only. The machine design is guided by our customers’ applications and processes. All components such as the optical system, the powder supply and the machine controls have been qualified in a multi-year practical use. Nevertheless, they represent latest available technology.

Future included

The decision to purchase an LMD system is always the result of careful considerations. A key requirement is a reliable and productive machine operation right from the beginning. However, decision makers often think one step further! Additive Manufacturing technologies show a rapid progress, and almost every day novel applications appear. Knowing this, we have made sure that future applications can be easily covered with LUNOVU pLMD systems.

This is achieved by a proprietary digital process chain. Furthermore, the mechanical setup, the optical system and the control system are designed in a strictly open and upgradeable manner. At any time, additional components and functionalities can be added. Needless to say that fast data exchange and a seamless intergration into production networks are a standard.

pLMD details

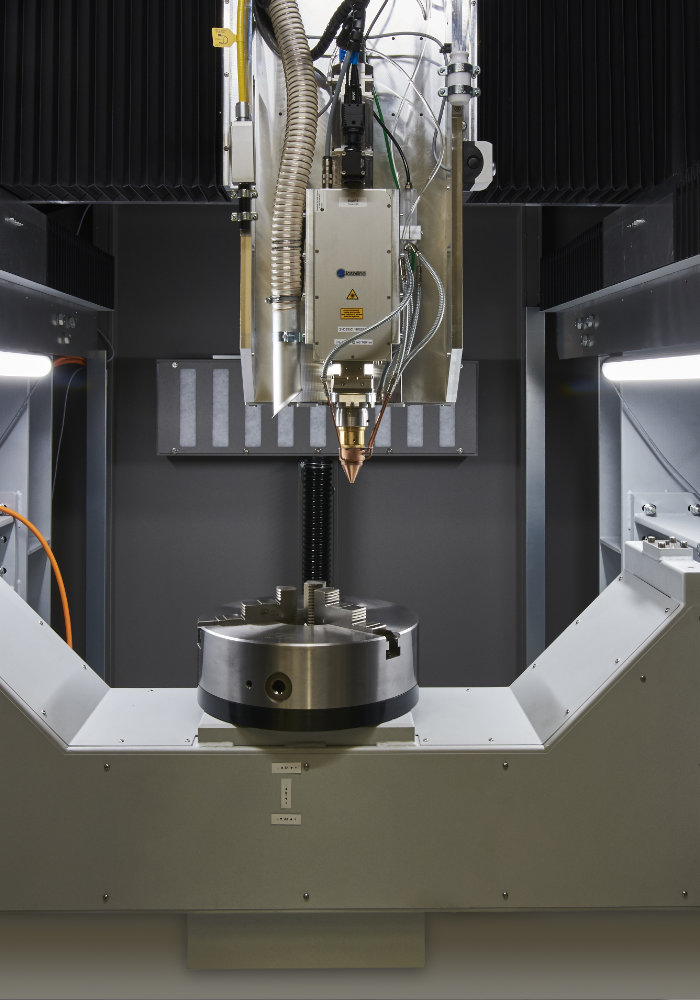

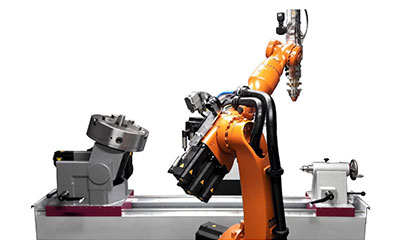

LUNOVU pLMD machines are designed as gantry systems. The XYZ system moves the processing head with optics, while the workpiece is positioned by a turn/tilt table in 5 axes operation. The machine frame consists of welded steel components and milled aluminum structures. On the one hand, this provides optimal accesssibility to the work area and, on the other hand, maximum rigidity and lowest vibration is achieved. The system has a modular design and is available in different sizes. Working spaces of severeal m³ ara available as standard. The turn/tilt unit has a tilt range of +/-90°, and an endless rotation. It is available for different loads from 100 kg to 500kg, in special versions also above.

Laser beam sources are direct diode lasers in the power range from 2 to 8 kW, optionally also higher. Depending on the application or on request, disk or fiber lasers can be also used. Various optical fibers and optics (with fixed focal length or as zoom optics) enable spot sites in a wide range that correspond to the application. A large number of powder nozzles (annular gap or multiple jet, round or rectangular spot) is available, as well as powder feeders with one or more powder containers.

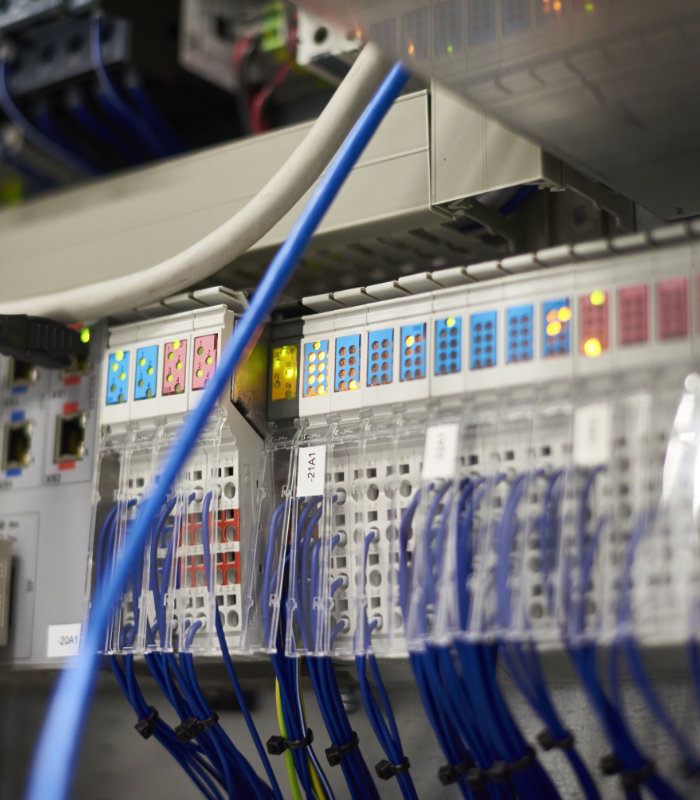

The pLMD system comes in a laser-proof housing (protection class 1) and can be conveniently loaded via a large safety door with a laser protection window. Upon request, accessibility for forklifts can be provided. Overhead sliding doors for loading with a crane can also be implemented. An extraction and filter unit is also part of the system. The CNC machine control is based on Siemens SINUMERIK One with LUNOVU’s own extensions, special functions and user interfaces.

A variety of materials and processes has already been pre-qualified so that corresponding processes can be transferred with the machine. Material classes are e.g. steel, nickel based or cobalt based alloys, aluminum alloys and special hard material mixtures (e.g. carbides in Ni based matrix).

pLMD systems are prepared for upgrades such as an extended, CAD-based toolpath planning (LunoCAM), pyrometers, thermal cameras, additional axes, clamping devices etc.