3D Additive Manufacturing fast and reliable

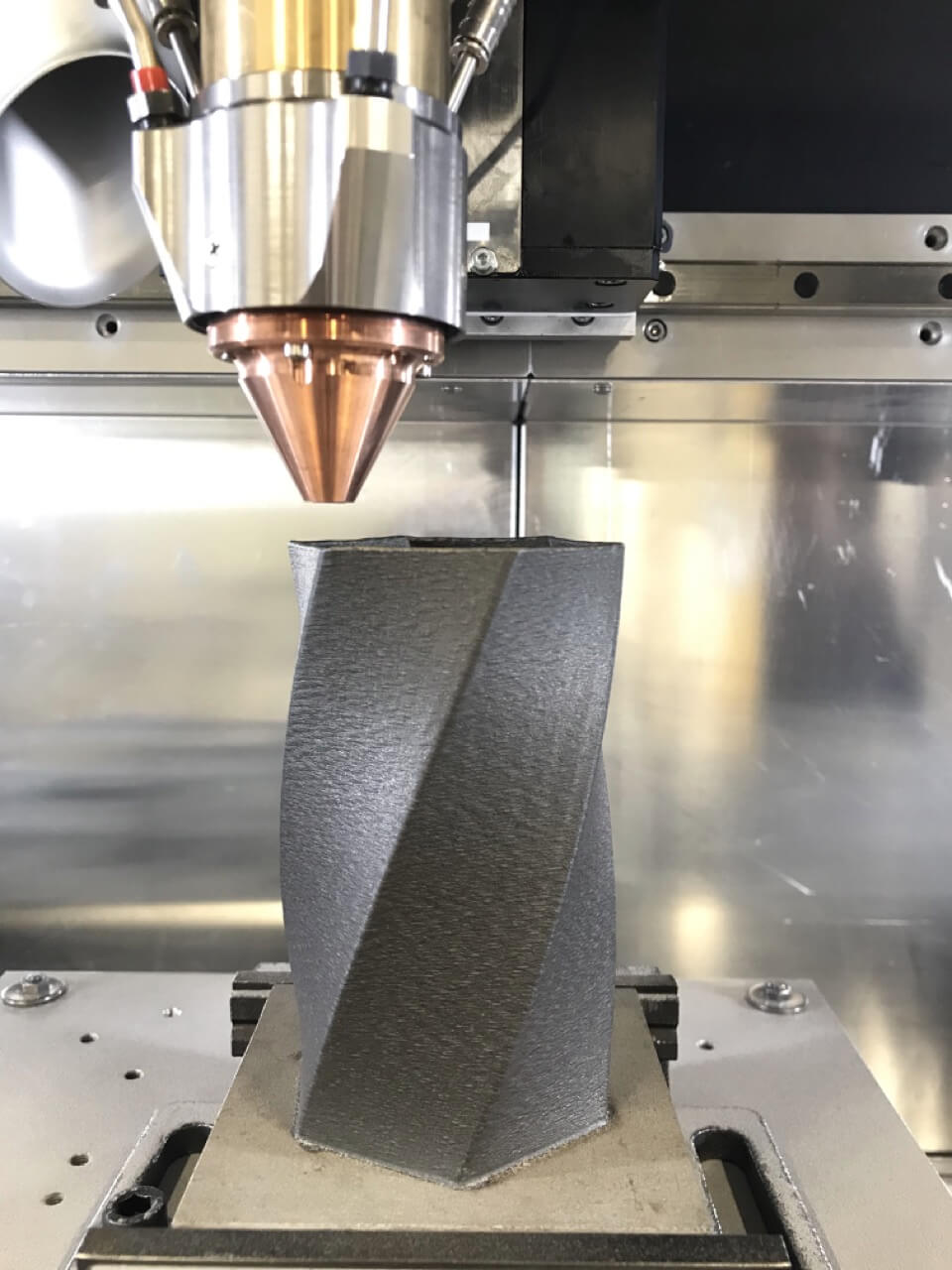

Creating three-dimensional metallic components directly from CAD data is certainly one of the most outstanding applications of LUNOVU LMD technology. It offers high build rates, the ability to manufacture different materials in one process, and last but not least, a superior material quality. At the same time, LMD/DED provides impressive flexibility. For example, it is possible to manufacture single-track thin wall structures, even with overhangs, which are realized without support structures. On the other hand, massive and large parts can be built quickly, with build rates well above 1 kg/h.

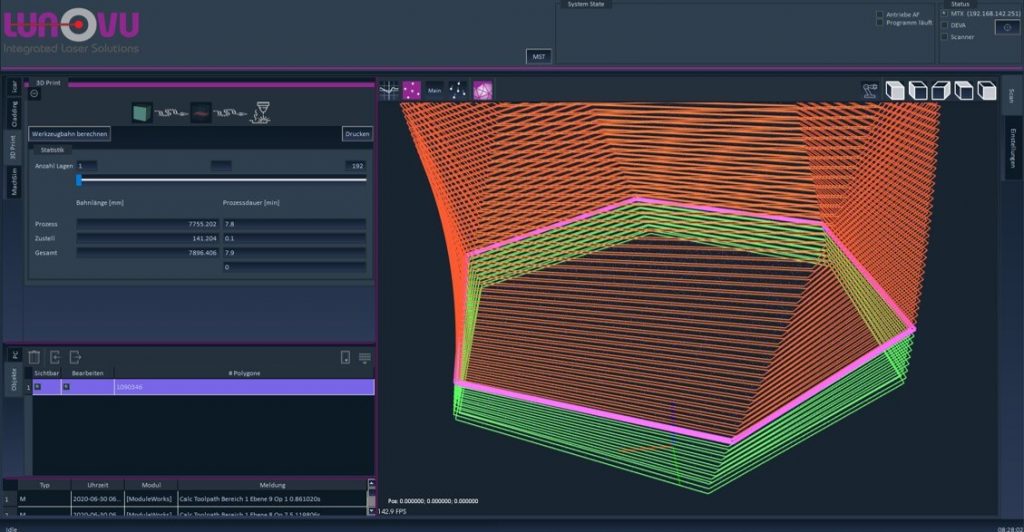

For additive manufacturing of 3D components, LUNOVU offers LunoBUILD, a simple and intuitive software environment. To build components on substrate plates (3-axis operation), it is sufficient to load an STL model and select LMD parameters in a few dialog boxes. The software splits the model into planes (slicing) and generates the required motion paths for each plane. The result is a completely automatically generated CNC or robot program for building the 3D part.

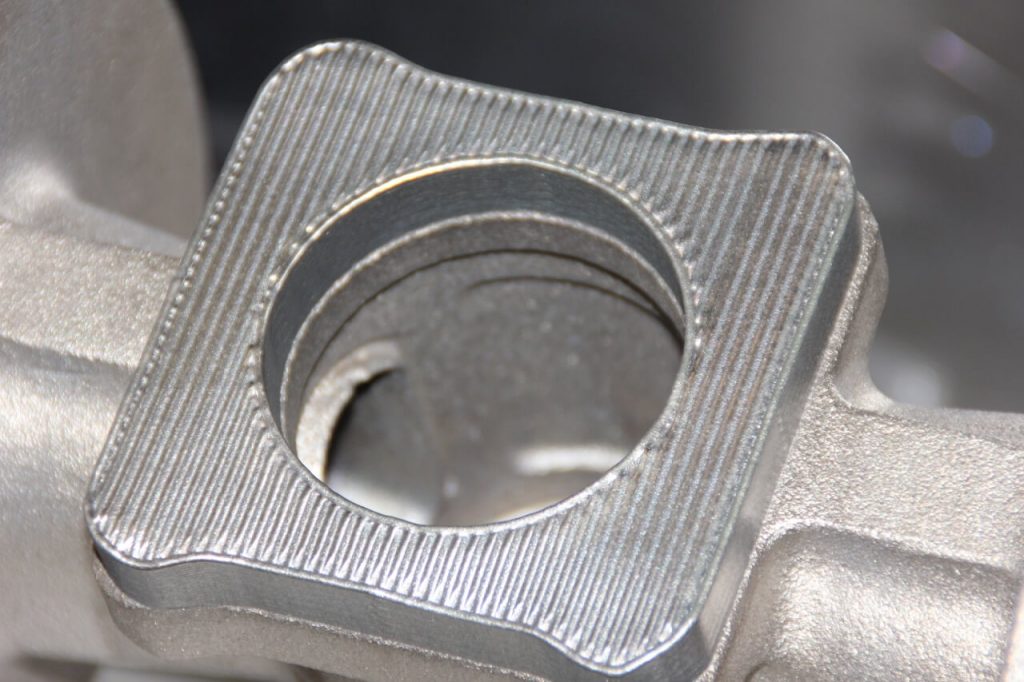

3D Additive Manufacturing on 3D Parts

A unique feature of LUNOVU machine systems is the possibility to build 3D structures on existing three-dimensional components, even if the original workpiece is not documented by CAD data. Here, the LUNOVU scan/path generation technology offers a reliable and efficient way to scan arbitrary components directly in the machine, and then build three-dimensional additions onto them directly from CAD files. In this way, customer-specific geometries can be applied to cast or forged parts, for example. Almost no preparation of the existing component is required. The process is extremely simply and time-saving, because no CNC programming is required. This is enabled by the LunoCAM software, which offers a variety of functionalities for advanced applications in a Rhinoceros® CAD environment.