- Machine Solutions

- rLMD robotic systems

rLMD robotic systems

Robot based DED / laser cladding machines at a new level

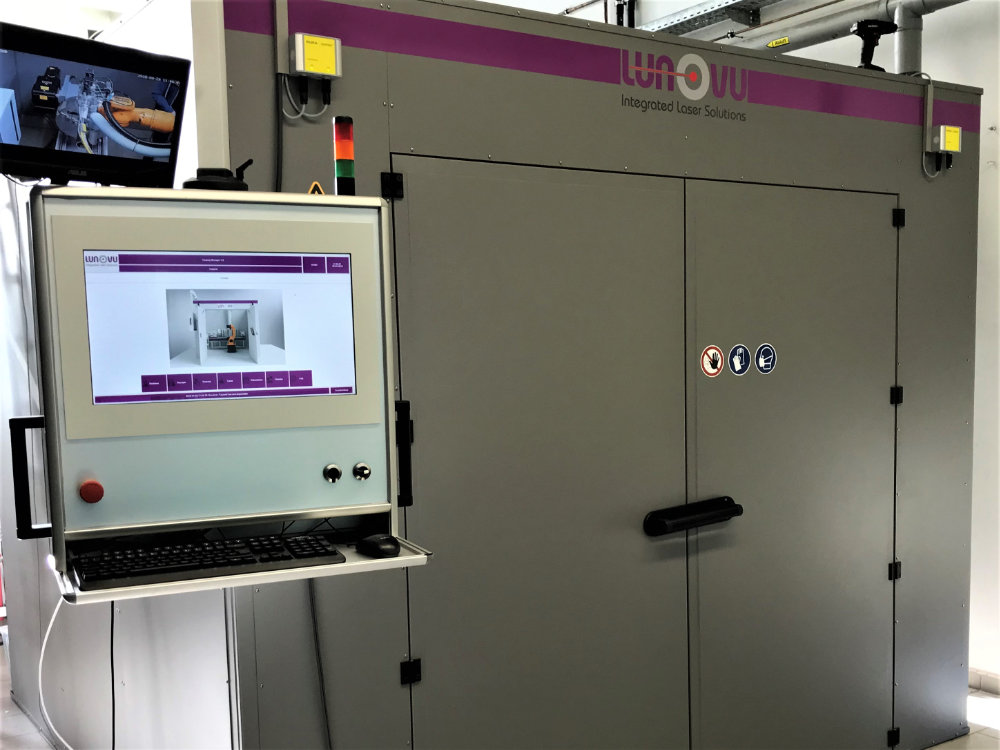

rLMD is a series of DED / laser claddding systems based on 6-axis articulated robots. Here, the competence of world market leading robot manufacturers merges with the unique process and control know-how of LUNOVU. The results are tailor-made systems for the each application, which are characterized by robustness, extremely reproducible process results and, above all, by an exceptionally user-friendly control architecture.

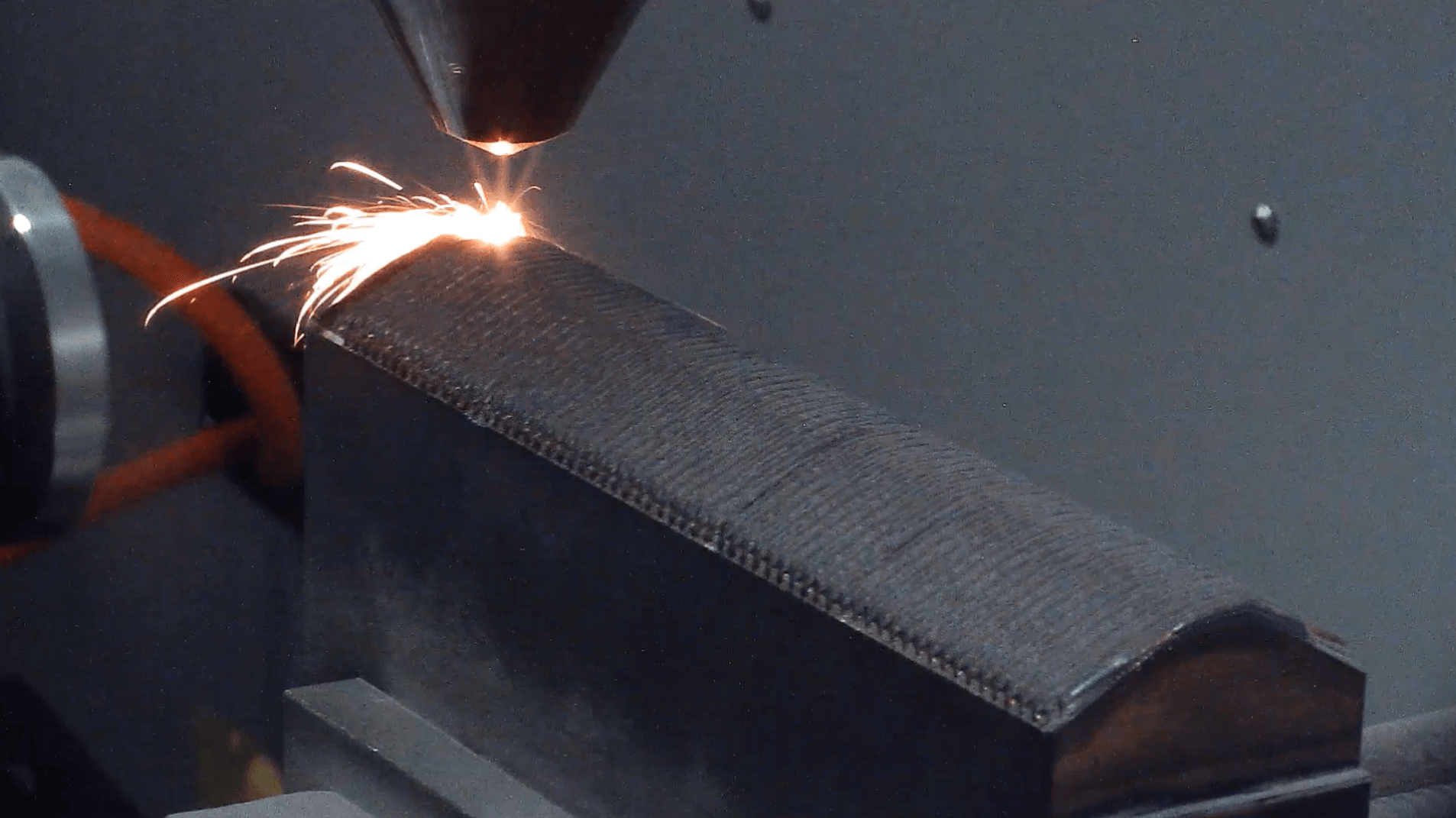

LUNOVU rLMD systems show their particular strengths in complex 3D applications – for example in the coating of free form surfaces or the repair of 3D geometries. Even on components for which no CAD documentation is available, the LUNOVU scan / toolpath generation solution can be used to implement complex DED processes in the shortest possible time and with almost no programming effort. This makes LUNOVU rLMD systems the first choice for applications in the field of laser cladding, wear protection or repair applications.

Performance and processes guaranteed

LUNOVU has its origins in control and automation technology. Thanks to our many years of experience, we know the specifics of robot systems exactly. And that is why we have decided to go beyond the classic system integration to implement truly complete robot DED solutions. The added value for our customers is obvious: As a laser cladding specialist, LUNOVU has an eye on the application and the process and delivers a holistic solution with defined performance, including processes for customer-specific applications.

Unlimited choices

rLMD systems are designed to be customer and application-specific. In a first step, we analyze your specific application together with you. If necessary, we are happy to carry out preliminary tests in our own application laboratory. Our process and application specialists will then find the optimal solution from a large number of possible robot configurations, laser beam sources, optics and powder systems. This way we can make sure that you will get an LMD system that serves your applications with maximum efficiency and robustness, at the same time delivering perfect process results.

rLMD details

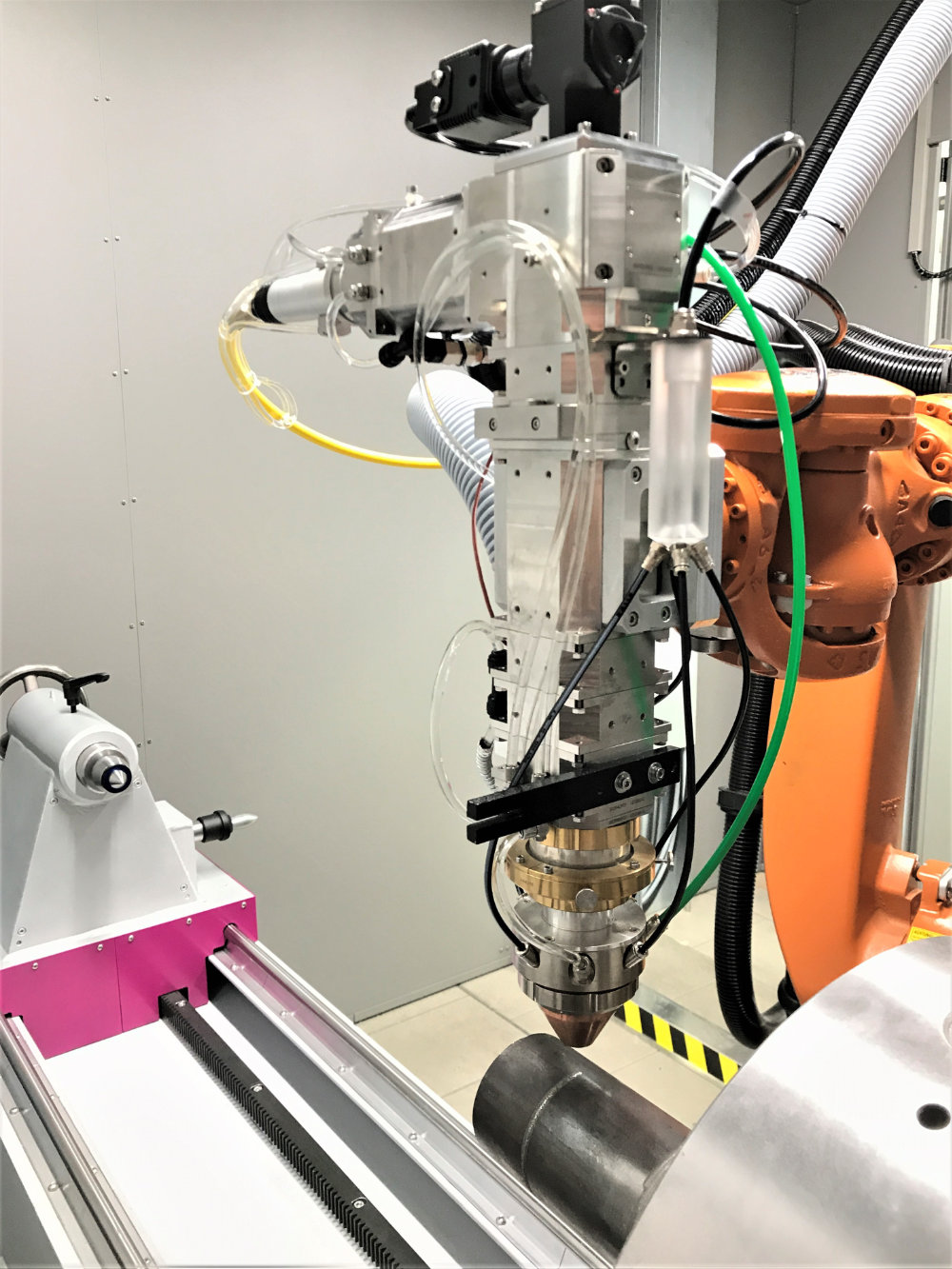

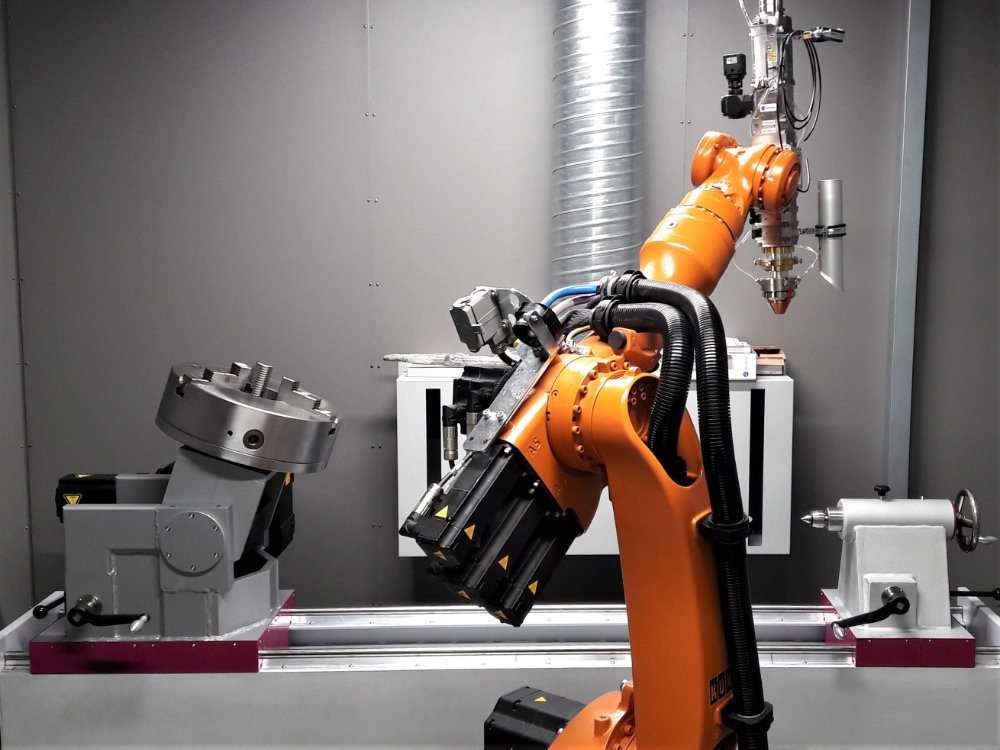

The basis of a LUNOVU rLMD system are usually 6-axis articulated robots from renowned manufacturers such as KUKA, ABB or Comau. Depending on the application, additional workpiece positioners are available as 7th/8th axis. Together with diode, fiber or disk lasers in a large power range, various powder feeders and powder nozzles selected for the respective application, they form the heart of every rLMD system. Of course, robots are available with a wide range of reach lengths. Additional linear units can also be used to enable even larger workspaces.

Different control options are available. For simpler applications, robot programs can be created directly with the robot software. On request, LUNOVU can supply higher-level software for the system control, which may include workpiece and process management or other features. Another option are virtually CNC controlled robots, where special software translates G code into robot code. The LUNOVU scan / toolpath generation software is widely used to boost productivity, especially for complex 3D applications, as it generates the robot code automatically for defined processing tasks without any programming effort. The basis for this are digital models of the parts to be processed. These models can be obtained from high-quality 3D scans that the LUNOVU rLMD system performs directly on the part to be processed, or CAD models that are loaded from external sources.

rLMD systems are completely surrounded by a safety enclosure which consists of double walls with an active monitoring. In the event of the slightest damage to one of the walls, the system is automatically brought into a safe state in the shortest possible time.